Image Source: www.diymotofix.com

How To Respoke A Dirt Bike Wheel: Step-by-Step

Can you respoke a dirt bike wheel yourself? Yes, you absolutely can! With patience and the right tools, respoking a dirt bike wheel is a manageable DIY project that can save you money and give you a deep sense of accomplishment. This comprehensive guide will walk you through every stage of the process, from gathering your materials to the final truing and tensioning.

Preparing for the Task: Gathering Your Supplies

Before you can begin lacing a new set of spokes, you need to ensure you have all the necessary components and tools. Trying to start without everything can lead to frustration and delays.

Essential Components:

- New Spokes: This is the most crucial part. Ensure you have the correct spoke kit for your specific dirt bike’s rim and hub. Spokes come in various lengths and thicknesses, and using the wrong ones will prevent proper lacing and truing. Always double-check your bike’s manual or consult with a reputable motorcycle parts supplier.

- Nipples: These small brass or aluminum pieces screw onto the ends of the spokes and thread into the rim. It’s often best to buy new nipples when you buy new spokes, as old ones can be corroded or damaged.

- Rim: The rim is the outer metal hoop that holds the tire. You’ll be working with your existing rim, or a new one if the old one is damaged beyond repair.

- Hub: This is the central part of the wheel that attaches to the axle. Like the rim, you’ll likely be using your existing hub.

- Rim Strip: This rubber or plastic strip protects the inner tube from the spoke nipples. Always replace this when respoking a wheel.

Key Tools You’ll Need:

- Spoke Wrench: This is a specialized tool designed to grip and turn spoke nipples. They come in various sizes, so ensure you have the correct one for your nipples. Having one with multiple sizes is a good investment.

- Tire Levers: For removing and installing the tire and tube.

- Tire Spoon (Optional but helpful): A wider, often curved lever that makes tire removal easier.

- Valve Core Tool: To remove and install the valve core for deflation/inflation.

- Bucket and Soapy Water: For cleaning the hub and rim.

- Gloves: To keep your hands clean and protect them from grease and sharp edges.

- Rags: For wiping down parts and cleaning up.

- Grease (Lightweight): A small amount for threading spokes into nipples.

- Thread Locker (Optional, for nipples): Some mechanics like to use a drop of blue thread locker on nipple threads for added security, but it can make future adjustments harder.

- Tire Mounting Lube or Soapy Water: To help slide the tire onto the rim.

- Air Compressor and Tire Gauge: For inflating the tire.

- Stands: A stand for the bike and potentially a wheel stand will make the job much easier.

- Measuring Tape or Caliper (for advanced truing): To measure runout precisely.

- Pen or Marker: To mark spokes if needed.

The Process: Step-by-Step Lacing and Truing

Wheel building dirt bike is a skill that improves with practice. The goal is to create a wheel that is strong, true (meaning it spins without wobbling), and has consistent spoke tension.

Step 1: Disassembly and Inspection

First, remove the wheel from your dirt bike. Then, carefully remove the tire, tube, and rim strip. You’ll need to unscrew each spoke nipple and remove the spokes. It’s often helpful to photograph or sketch how the spokes are laced before you start removing them, especially if you plan to reuse the old rim and hub. As you remove each spoke, inspect the hub’s spoke holes and the rim’s spoke holes for any damage or wear. Check the nipples as well.

- Hub Inspection: Look for cracks, enlarged spoke holes, or worn bearing surfaces.

- Rim Inspection: Check for dents, cracks, or corrosion, especially around the spoke holes. If your rim is significantly damaged, it might be more cost-effective to replace it entirely.

Step 2: Preparing the Hub and Rim

Clean both the hub and the rim thoroughly. Use soapy water and a rag to remove any dirt, grease, or old corrosion. A wire brush can be useful for stubborn grime, but be gentle around the spoke holes. Ensure all surfaces are dry before proceeding.

Step 3: Lacing the Wheel: The Foundation of Wheel Building Dirt Bike

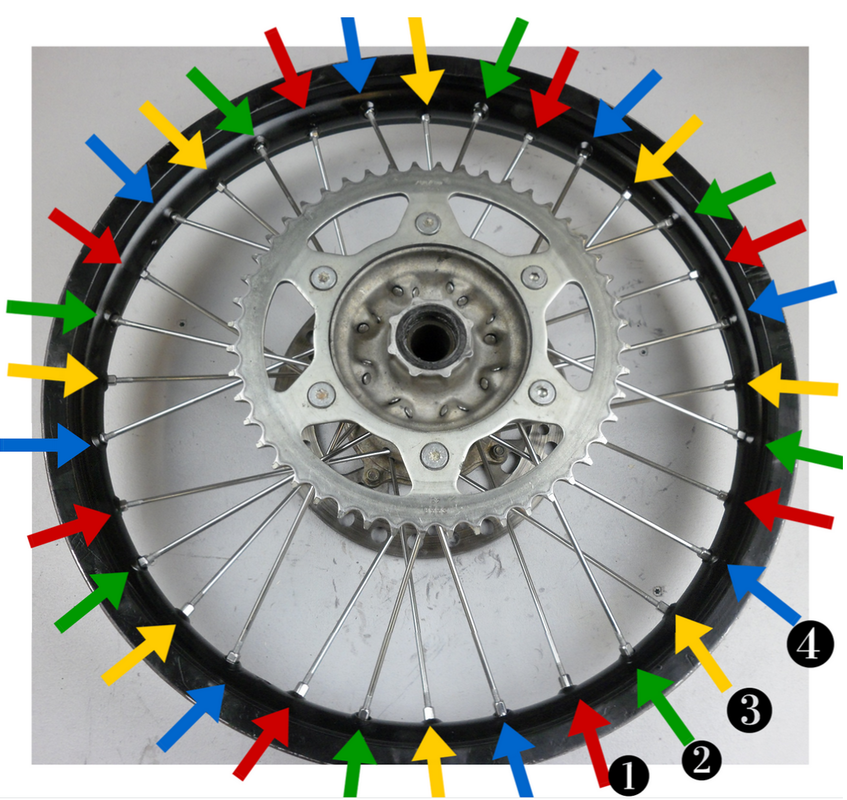

This is where the magic happens. The way you lace the spokes is critical for the wheel’s strength and balance. Dirt bike wheels typically use a “three-cross” lacing pattern. This means each spoke passes over three other spokes on its way to the rim.

Important Considerations for Lacing:

- Spoke Direction: Spokes are often “butted” or have a bend near the head. Ensure the bend faces the correct way for your hub. Some hubs have spokes that radiate outward, while others have spokes that angle inward. Consult your hub’s design.

- Rim Hole Orientation: Rims often have offset spoke holes to accommodate the dished nature of the wheel (the rim isn’t perfectly centered between the hub flanges). You need to lace the spokes through the correct holes in the rim.

The Three-Cross Lacing Pattern:

- Start with the Hub: Identify the spoke flanges on your hub. They usually have pairs of holes on each side.

- Insert First Set of Spokes: Take a spoke and thread it through a hole in one of the hub flanges. Screw a nipple onto the spoke a few turns. Now, guide this spoke to the rim. Find the correct hole in the rim according to the three-cross pattern. You’ll be skipping two rim holes and going into the third.

- Continue Around the Hub: Insert another spoke into the hole next to the first one on the same flange. Again, screw on a nipple and guide the spoke to the rim, following the three-cross pattern. This second spoke will be laced in the opposite direction to the first.

- Working Across the Hub: Now, move to the opposite side of the hub flange. Insert a spoke and lace it to the rim, again following the three-cross pattern. This spoke will go into a rim hole that is in line with the first spoke you laced.

- Complete the First Side: Continue this pattern, working around one side of the hub and lacing spokes to the rim. You will have spokes going in alternating directions from the hub. For a typical 36-spoke wheel, you’ll lace half the spokes from one side of the hub, then move to the other side.

- Second Side of the Hub: Once you’ve laced all the spokes from one side of the hub, move to the other side. The spokes from this side will cross over the spokes from the first side. You’ll be filling the remaining holes in the rim.

Tips for Lacing:

- Keep Nipple Snug: Screw the nipples on just enough so that the threads are covered, but not so tight that the spokes are under tension yet.

- Visual Check: Constantly check that you are following the correct pattern and that the spokes are going into the correct rim holes.

- Don’t Force Anything: If a spoke doesn’t seem to fit correctly, re-check your pattern and the orientation of the spoke and rim holes.

Step 4: Initial Spoke Tensioning

Once all the spokes are laced, you need to start tightening the nipples. The goal here is to bring the wheel up to a consistent, low level of spoke tension.

- Snug Up All Nipples: Go around the entire wheel and tighten each nipple until it’s snug. The spokes should be taut but not under significant pressure. You should be able to deflect them slightly with your fingers.

- Use Your Spoke Wrench: Use your spoke wrench to make small, even turns.

- Count Turns (Optional but Recommended): Some people like to count the number of turns they make on each nipple to ensure consistency. For example, if you tighten all nipples until they are snug and then give each one another 5 turns, you’re creating a baseline.

Step 5: Truing the Wheel: The Art of Adjusting Spokes

Truing a dirt bike wheel involves correcting any side-to-side wobble (lateral runout) or up-and-down wobble (radial runout). This is done by carefully adjusting the spoke tension. Spoke tension dirt bike wheels need to be high and consistent for durability.

Understanding the Truing Process:

- Lateral Runout: This is when the rim wobbles left or right as it spins. To correct this, you’ll tighten spokes on the side opposite the wobble. For example, if the rim is wobbling to the left, tighten spokes on the right side of the hub.

- Radial Runout (High/Low Spots): This is when the rim dips or rises as it spins. To correct a high spot (where the rim is out too far), you’ll tighten the spokes going into that section of the rim. To correct a low spot, you’ll loosen the spokes in that area.

How to True Your Wheel:

- Mount the Wheel: Secure the wheel in a stand or on the bike.

- Identify Wobbles: Spin the wheel slowly. Use a fixed point (like a zip tie attached to your fork or frame, or a dedicated truing stand) to gauge the runout. Watch the gap between the rim and your reference point.

- Make Small Adjustments:

- Lateral Wobble: If the rim is to the left at a certain point, tighten the spokes on the right side of the hub that connect to that section of the rim. If the rim is to the right, tighten spokes on the left.

- Radial Wobble: For a high spot, tighten the spokes in that area. For a low spot, loosen the spokes in that area.

- Even Tension is Key: The most critical part of adjusting spokes dirt bike is to make small, even adjustments. Turn nipples only a quarter or half turn at a time.

- Work in Stages: Don’t try to fix everything in one go. Make some adjustments, spin the wheel, check again, and repeat. You’ll be chasing the wobble around the wheel.

- Balance Tightening and Loosening: When you tighten spokes on one side to correct a lateral wobble, you’re also increasing the tension across the wheel. Be mindful of this. Often, you’ll be tightening some spokes and loosening others.

- Check Rim Strip Clearance: As you tension the spokes, ensure the rim strip is still seated correctly and not pinched.

Step 6: Achieving Proper Spoke Tension

This is perhaps the most challenging aspect for beginners and a crucial part of dirt bike wheel maintenance. Proper spoke tension provides strength and prevents the wheel from deforming under stress.

- The “Spoke Tension Dirt Bike” Goal: You want a consistent, high tension across all spokes. The spokes should “ping” with a clear metallic note when plucked, not sound dull or slack.

- Using a Spoke Tension Gauge: For the most accurate results, a spoke tension gauge is highly recommended. This tool measures the actual tension of each spoke. You can then compare your readings to the manufacturer’s specifications or to a known good wheel.

- The “Feel” Method (Less Precise): Experienced mechanics can often judge spoke tension by feel and sound. However, this takes a lot of practice. As a general rule, spokes should be tight enough that you can’t easily deflect them with your finger, and they should have a similar “ping” sound when plucked.

- Gradual Increase: Continue to gradually increase tension, making small adjustments and spinning the wheel to check for new wobbles.

- Alternating Sides: When increasing tension, work in a pattern that alternates sides of the hub and crosses to maintain balance.

Step 7: Final Checks and Reassembly

Once you believe the wheel is true and the spoke tension is consistent:

- Final Truing Pass: Spin the wheel one last time, checking for any remaining wobbles. Make any minor adjustments needed.

- Check for Loose Nipples: Go around and give each nipple a final snug with the spoke wrench.

- Reinstall Rim Strip and Tube: Ensure the rim strip is perfectly centered. Install the inner tube and inflate it to a low pressure to help seat the tire.

- Mount the Tire: Use tire levers and lube to carefully mount the tire. Avoid damaging the rim strip or tube.

- Inflate the Tire: Inflate the tire to the recommended pressure for your dirt bike.

- Reinstall the Wheel: Put the wheel back on your dirt bike and tighten all axles and brake components.

Maintaining Your Newly Spoked Wheel

Proper dirt bike wheel maintenance doesn’t end with respoking. Regular checks will prolong the life of your wheel and ensure it performs optimally.

- Regular Spoke Tension Checks: Periodically check your spoke tension, especially after the first few rides on a newly respoked wheel. Spokes can settle, and tension can change.

- Visual Inspection: Look for any bent or broken spokes, loose nipples, or damage to the rim or hub.

- Cleaning: Keep your wheels clean. Dirt and grime can hide potential problems and can contribute to corrosion.

Frequently Asked Questions (FAQ)

Q: How long does it take to resRoke a dirt bike wheel?

A: For a first-timer, it can take anywhere from 2 to 4 hours, or even longer if you encounter difficulties. Experienced mechanics can often do it in under an hour.

Q: Is it worth respoking a dirt bike wheel yourself?

A: Yes, if you’re willing to invest the time and learn the process. Professional wheel building can be expensive, and DIY respoking can save you a significant amount of money.

Q: What are the signs that a dirt bike wheel needs respoking?

A: Signs include wobbling, spokes breaking regularly, loose spokes, bent spokes, or a rim that is visibly out of true.

Q: Can I reuse old spokes?

A: It’s generally not recommended. Old spokes may be stretched, weakened, or corroded, which can lead to premature failure. Always use new spokes for a rebuild.

Q: What is the difference between lacing and truing?

A: Lacing is the process of installing the spokes into the hub and rim. Truing is the process of adjusting spoke tension to make the wheel spin straight and round.

Q: How tight should spokes be on a dirt bike?

A: Spokes should be tight and provide a consistent “ping” when plucked. Using a spoke tension gauge to achieve manufacturer-specified tension is the best method.

Q: Can I just tighten loose spokes without respoking the whole wheel?

A: You can tighten individual loose spokes to improve tension, but if the wheel is significantly out of true or has damaged spokes, a full resRoke is necessary.

By following these steps, you can successfully resRoke your dirt bike wheel, ensuring it’s strong, true, and ready for the trails. Remember that patience and attention to detail are your best allies in this process.